You can download our product information in PDF under each product page.

If you do not have Adobe Acrobat Reader installed, please download it for free here. |

|

|

|

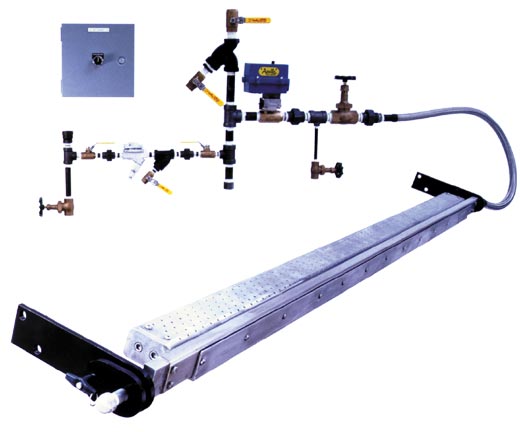

MODEL ESA-1 STEAM ASSIST

Download product information in PDF here (  1.04 MB) 1.04 MB)

|

|

|

|

Improved Bonding Quality / Faster Multi-Wall Speeds / Faster Heavy Liner Speeds / Stainless Steel Construction / On/Off/Auto Control / Motorized Valve For Positive Control / Safety Improvements Incorporated

The Model ESA-1 gives you a competitive edge in both production

speed and the quality of your adhesive bonding. Performance,

reliability, and controllability are the hallmarks of

our Model ESA system.

The

Model ESA-1 Steam Assist bar is fabricated from durable

stainless steel to provide long years of service. The

ESA-1 improves production speeds of multi-wall webs and

heavy weight liners by introducing heat directly to the

glue lines prior to bonding. This permits the adhesive

to “pre-gel” by raising the BTU level of the glue line

before the double backer and better insures that the adhesive

will have enough heat to set, bond, and cure before reaching

the cut-off end of the machine. All the safety features

incorporated since this equipment was first introduced

to the corrugating industry will be found in the ESA-1. The

Model ESA-1 Steam Assist bar is fabricated from durable

stainless steel to provide long years of service. The

ESA-1 improves production speeds of multi-wall webs and

heavy weight liners by introducing heat directly to the

glue lines prior to bonding. This permits the adhesive

to “pre-gel” by raising the BTU level of the glue line

before the double backer and better insures that the adhesive

will have enough heat to set, bond, and cure before reaching

the cut-off end of the machine. All the safety features

incorporated since this equipment was first introduced

to the corrugating industry will be found in the ESA-1.

A Motor Operated Valve is activated by the machine speed switch and steam flow is

controlled by a simple switch. The perforations on the bar now originate approximately

6” (15 cm) inside your maximum paper width to prevent operators from getting too close

to the live steam. The bar is also constructed with interchangeable ends to permit the

plant to install the Steam Assist in either a left hand or a right hand machine.

All of the performance and craftsmanship translate into higher quality, faster production

speeds, lower waste, and a greater margin of safety for the plant and operating personnel. |

|

|

|